The AIT-STEIN group has been mandated by SUEZ as part of its HELYSEO project for its AZALYS site, a waste treatment and energy recovery plant in the municipality of Carrières-sous-Poissy (78). Suez called on us for the supply and upstream installation of an SCR of two smoke heaters, replacing their gas burners, as well as the associated network of steam supply and condensate supply piping. The goal? Improve the energy performance of our customer’s installation with our tailor-made solutions.

Performance optimization combined with a reduction in the carbon footprint: a winning duo.

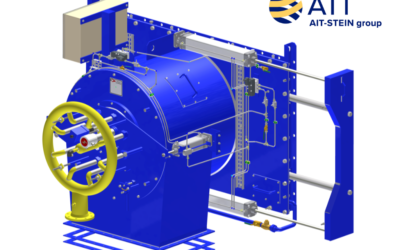

Both smoke heaters were designed by our Air Industrie Thermique (AIT) entity and manufactured in our COMECO workshop. Connected to a steam balloon by an independent steam line, each heater has its own condensate purge station. At the outlet of the traps, the condensate networks of the two steam heaters are connected in order to have a single connecting piping for the return of the steam/condensate mixture to the customer’s MP barrel. The equipment and pipes installed have been insulated* to limit heat loss.

The elimination of gas burners reduces the consumption of 156 Nm3/h of natural gas, a reduction of about 2,500 tons/year of CO2. As an example to illustrate this data, to absorb 2,500 Tons/Year of CO2, it would have been necessary to plant 83,567 trees/Year, or 17 Hectares/Year**. We were able to determine this data thanks toour internal thermal calculation application (for more information about our application,it’s here). These indications, such as the amount of CO2 not produced and the equivalence in trees recoveredover a period of one year, echo the reduction of the environmental impact of our customers thanks to our solutions.

“It is always very motivating to get involved in a complex project that will have a real impact in the energy transition, while taking into account the real constraints of customers: productivity and performance. And what a pleasure to see it successfully realized! Engineering, manufacturing, integration, mastering the entire value chain allows us to support our customers from A to Z.” Morgan Grisolet, Proposal Engineer.

Management of smoke control: direct impact on efficiency improvement.

By integrating the design and installation of steam/condensate networks and the smoke temperature control system, AIT-STEIN provides Suez with a complete guarantee on the performance of the installation and ensures global solution integration by limiting the interfaces between different batches. Due to a loaded space on the existing installation, on-site surveys were carried out using a 3D scan, allowing an optimization of the pipe layout.

“Once again, the expertise of the AIT-STEIN group has enabled its customer to recover energy. The synergy carried by the group’s entities is our strength. »Constance Morin, Project Manager Air Industrie Thermique (AIT).

The supply of the smoked ducts comes from the company CARAMEAUX and the assembly of the heaters and the piping network was carried out by our service provider BRAILLON.

LinkedIn Post* Conçus avec des matériaux ayant un fort potentiel isolant. ** Sur une base de 30 kgCO2/an/arbre et 5 000 arbres/Hectare.