Rueil-Malmaison, 3 september 2020

A water-responsible site. This is the Valence Romans Urban Community’s objective, which has undertaken to respect the IWA Principles (International Water Association). The aim of these Principles is to optimise management of all the city’s water through collaborative actions between local decision-makers, professional actors and individuals.

The Valence Urban Community is part of a sustainable development approach whose primary objective is the fight against climate change (in particular the reduction of the carbon impact). One of the main objectives of the Valence Romans urban community is the development of renewable energies such as biogas, mainly made up of methane and produced during anaerobic digestion1 of products from wastewater treatment on the site of the Valence water treatment plant, one of the main plants in this Community.

Today, Veolia, the operator of this water treatment plant, is calling on AIT-STEIN to renovate the flue gas heat recovery system, to improve energy recovery from the sewage sludge and reduce the carbon impact.

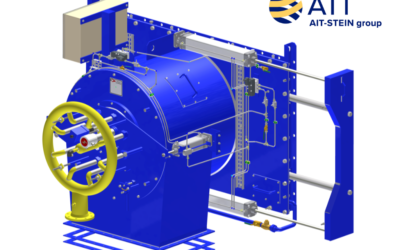

The existing installation is composed of two AIT-STEIN exchangers installed on the flue gas circuit downstream of the fluidized bed sludge incinerator since it was built in 2001.

As far as the renovation itself is concerned, it is divided into two phases. Initially, the first AIT-STEIN exchanger, a fume-tube recuperator type, will be entirely replaced and will retain its function of preheating the furnace fluidization air. The second AIT-STEIN exchanger will be replaced by a fume-tube boiler which will produce superheated water. This boiler has a double function: on the one hand, it cools the flue gases to reduce the temperature to acceptable values for the treatment of flue gases (filtration and depollution), and on the other hand, via its association with a superheated water loop, it provides the energy necessary for the operation of a digester which is part of the anaerobic digestion process.

The Group’s objectives of reducing carbon impact for green growth are in alignment with this project. Among other things, it will offer an efficient solution for treating products from wastewater treatment in the Community and neighbouring territories and will reduce the final quantity of sludge residues to be treated by minimizing the costs of thermal treatment (incineration).

AIT STEIN offers you more ethical, comprehensive and adapted solutions according to your needs while also controlling production costs.

Key figures:

-11% reduction in electricity consumption at the Valencia wastewater treatment plant

-Electricity savings on the 3 main wastewater treatment plants (Romans, Valence, Portes) are estimated at 1.14 Gwh, i.e. equivalent to the electricity consumption of approximately 250 homes.

-Weight of the skimmer 4 tons. Dimensions: 5m high, Ø 1.1m.

-Weight of the boiler 9.7 tons empty and 21 tons with water. Dimensions: 9m high, Ø 1.2m.

-Recuperator power 740 KW maxi 1200 KW

-Boiler power 715 KW maxi 1264 KW